New era of clean, efficient hydrogen production is here — delivering scalable, cost-effective energy solutions for industries worldwide.

ACT is a private green hydrogen technology & development company preparing for commercialization of technology in numerous industries and applications.

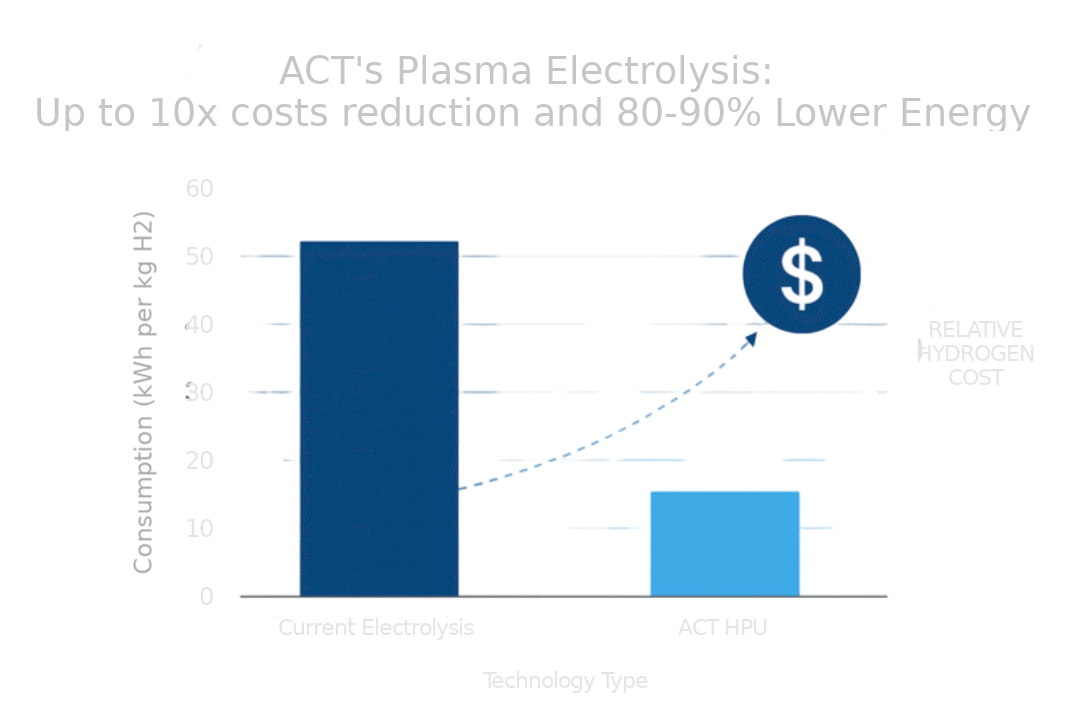

ACT’s patented plasma electrolysis technology has unlocked exceptional efficiencies to produce green hydrogen on par with natural gas.

The demands for energy are unprecedented today; with execution and scaling, we foresee a future of ACT Hydrogen offering the cheapest, most reliable energy of any kind across the globe…with water.

years of experience

In 2025:

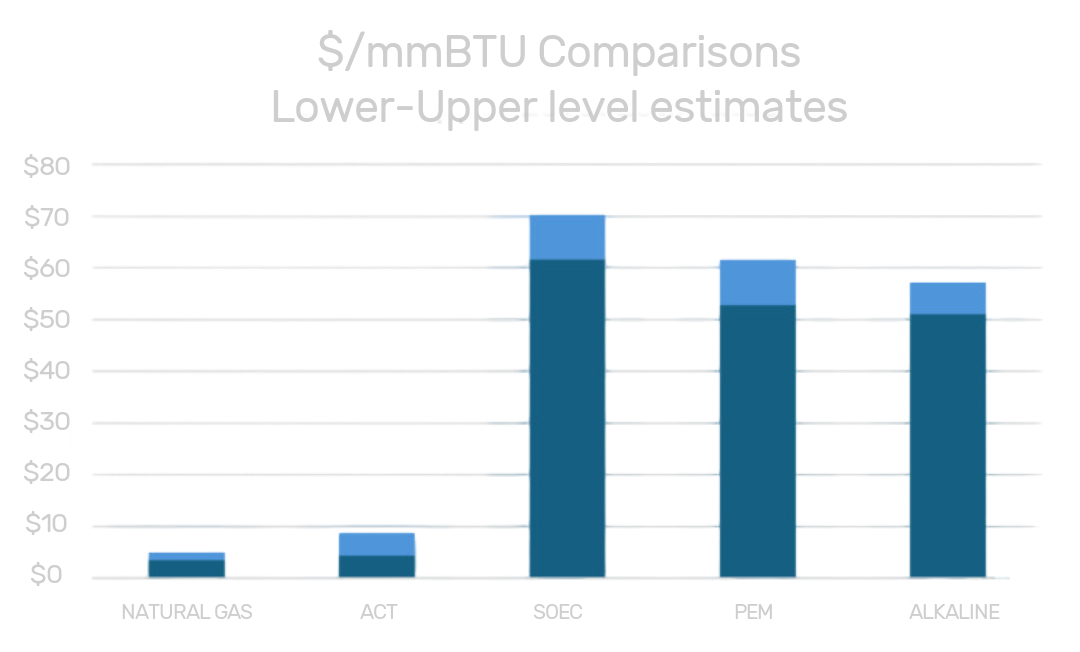

Natural Gas /MMbtu = ~$4.00

By comparison, the three prevalent commercial Green H₂ methods cost an estimated $52-70 / mmBTU*

ACT will produce Green H₂ at or below natural gas under fixed, long term Power Purchase Agreements with partners ensuring price certainty and a reliable source of Green H₂.

H₂ purity of up 99.99% along with Oxygen produced continuously where it’s needed for various applications.

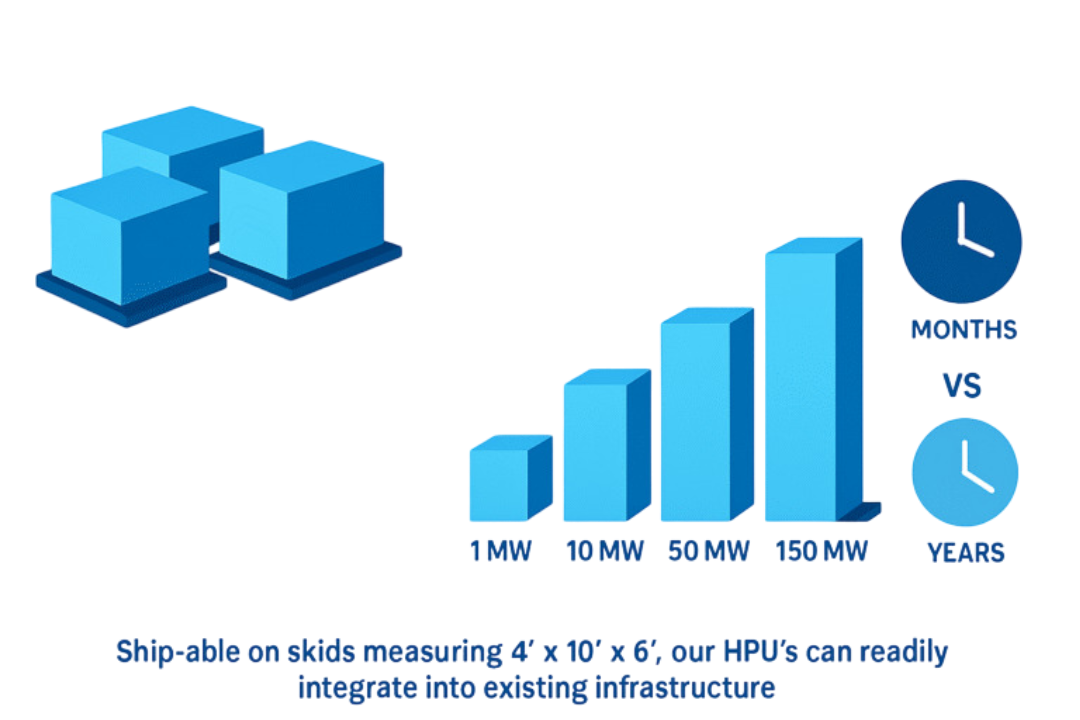

Two HPU units providing 1+ MW each can be shipped in a single shipping container with a similar footprint when installed. Our design allows for scaling up to 200 MW and beyond as required.

Instead of years, our installation and deployment projects can be completed in months.

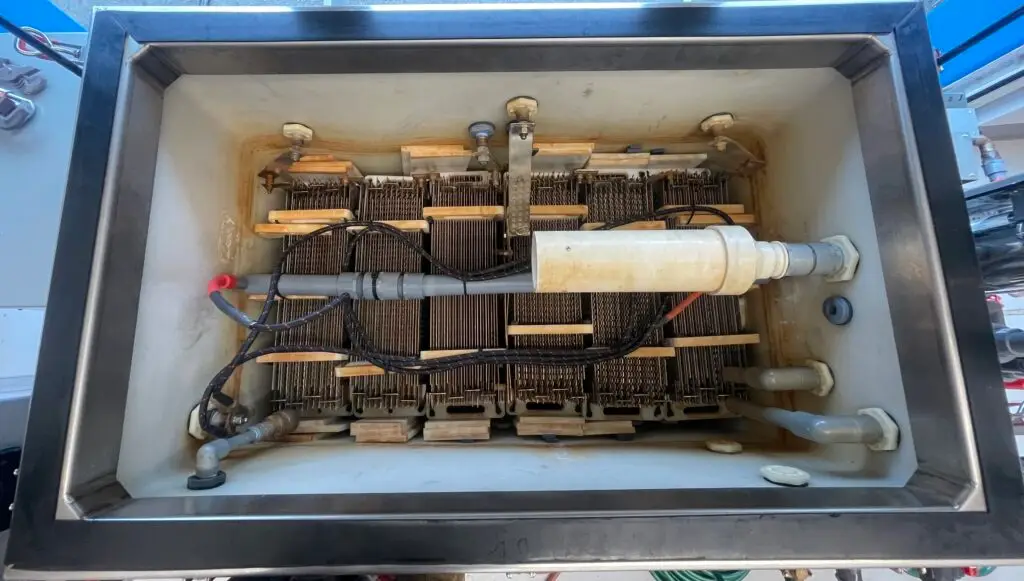

ACT’s Hydrogen Production Unit (HPU) utilizes a novel and internationally patented technology that applies a phase-shifted plasma electrolysis method to produce hydrogen and oxygen at atmospheric pressure from a potassium hydroxide solution of deionized water.

Through resonant frequency enhancements applied to our dual-pulsing plasma process, our HPUs will cut the cost of green hydrogen by over 80%. Current commercial electrolysis requires 50-60 kW of electricity to produce 1 kg of H₂. We have demonstrated the potential to use 3-7 kW/kg green H₂. While precise real-world production results are pending, we anticipate upending the economics of hydrogen by cutting the cost of green hydrogen to well below $1/kg.

Improvements are underway to upgrade our plated cathode and anode materials and tank structuring.

We will share updates on our newest HPU soon.

For a look back on the history of our development, see below.

ACT Hydrogen was founded in 2008 by Chas Radovich and Gary Betherum in an 8,300 ft² lab in Chatsworth, CA. Chas brought in Robert Plaisted as the first Chief Science Officer, who took an entirely new angle to electrolysis and hydrogen production. Through trial, error, and relentless pursuit, we uncovered new principles to elevate theoretical efficiencies of electrolysis beyond what anyone deemed possible.

Tragically, Gary passed away from ALS in 2017. But Chas was determined to carry on their shared vision of transforming hydrogen production technology. Our team, led by Robert, continued development, testing, and improvements, even extending into research related to applying the technology to the manipulation of hydrocarbons.

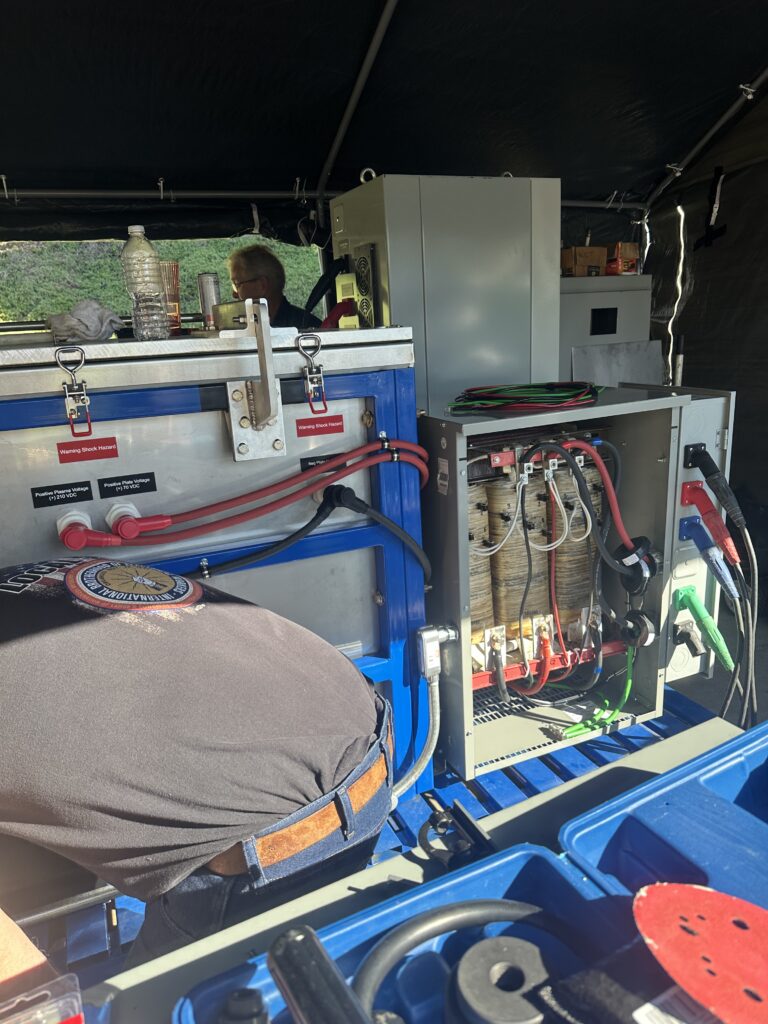

A major breakthrough occurred in 2018 when our technology advanced away from known Faraday’s laws of electrolysis and began implementing a dual pulsing plasma process. As the fourth state of matter, plasma had been largely untested in this application and has proven integral to our success.

In 2021, ACT was introduced to NAER as they searched for a new green hydrogen solution. As an international power supply company with experience in building, refurbishing, and improving power generation plants in multiple industries, they recognized the potential in the new hydrogen technology that ACT Hydrogen could offer.

n 2022, NAER conducted their own independent testing of our technology and were amazed by the potential efficiencies and hydrogen production they observed.

Since then, ACT and NAER have worked hand-in-hand to advance our technology from the lab to commercial application. Our partnership with NAER has been invaluable in R&D, manufacturing, and arranging our Pilot Project with California Power Partners in Q1 2026.

In 2024, ACT entered into a collaboration with the nation’s leading fuel research laboratory at UC Irvine’s HIMaC Laboratory, headquarters of the $1.2 billion ARCHES Hydrogen Energy Hub. During our first lab-to-real-world trials from May-September 2025, we established proof of concept while stress testing and identifying multiple improvements to enable field durability for continuous operations.

Limited-scale manufacturing of our first commercial HPU is underway to power our first pilot project in January 2026. We will also deliver a new HPU unit to HIMac for continued testing and material science collaboration through the end of 2026.

Founder / CEO

Corporate Secretary

CEO - Europa, Africa & MIddle East

IT Director

Business Development Administratio

Director Business Contract Development

Business Development

Chief Science Officer

Project Engineer

Advisory Board Member, Hydrogen Industry Pioneer

Consultant and Advisor

Co-Founder

Advisor, Inventor, Legend. 600+ lifetime patents.

Hydrogen Industry Pioneer.

Mentor, Teacher, Leader. Detroit Manufacturing Titan.

Our pilot HPU will be installed into the facility in order to augment through Syn-Gassing the onsite power production generated by methane harvested from the from the Facility’s wastewater treatment process. All licenses and approvals have been completed and installation will begin in January 2026.

Expected to be operational by March 2026, this keystone project will establish proof of concept, unlocking significant capital, as well as refine our designs for large scale manufacturing

Through partnerships with PTI, Milton, and others, we will commence mass production in 2026 to supply our first large scale projects.

ACT will manufacture and partner to provide all HPU’s in partnership with NAER’s contract as the EPC set to begin in 2026.

ACT has a large list of very interested partners with whom we have been in discussions for years and are eager to implement out technology as soon as we can provide it. These companies include